Awarded Paper Proposes 3D Radio Channel Model for Industry 4.0

Three researchers at the Centre for Wireless Communications (CWC), which is leading the 6G Flagship Program, co-authored a conference paper “Industrial Indoor Measurements from 2-6 GHz for the 3GPP-NR and QuaDRiGa Channel Model” which was awarded as the Best Overall VTC2019-Fall Paper.

The article builds on key results of Reicovair project in which the CWC team planned and carried out radio channel measurements in extremely challenging industrial scatter environments. The results are especially important for Industry 4.0, in constantly changing wireless conditions.

We asked eight questions of the CWC authors Risto Vuohtoniemi, Marko Sonkki and Veikko Hovinen about the technical challenges and specifications of the realized measurements. This is what they answered.

Why are reliable low latency wireless links especially important for Industry 4.0?

Reliable low latency communication is the key enabler for tele operation of industrial machinery. So far, majority of industrial communications has been done by wired links. These links can tolerate interference from other telecommunications systems, the propagation path does not change over time, which all make the systems resilient to errors that may affect to the system performance. Latency is constant and depends only on the number of bridges and the length of the wired path. When we enter to a constantly changing wireless environment, scientific challenges become more complicated as radio channel is unpredictable. To minimize the latency in wireless links, radio channel conditions need to be studied and modelled in several different propagation environments.

What is currently missing from accurate radio propagation channel models in industry environments?

It is very important to make channel measurements and get information of the parameters to be used in the propagation modelling. Current models are simplified statistical models that are not able to predict the propagation conditions well enough.

What kinds of problems may arise in practice as a result of inaccurate channel models?

When wrong channel state predictions are done in the receiver, the data rates get lower and the latencies increase, and in the worst case the whole communication link fails.

What are the specific challenges in industrial indoor scenarios that you have explored in the article?

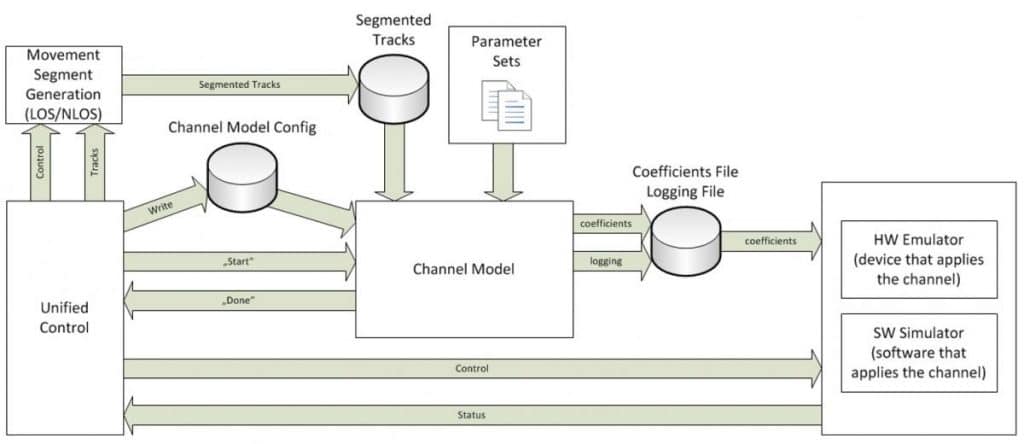

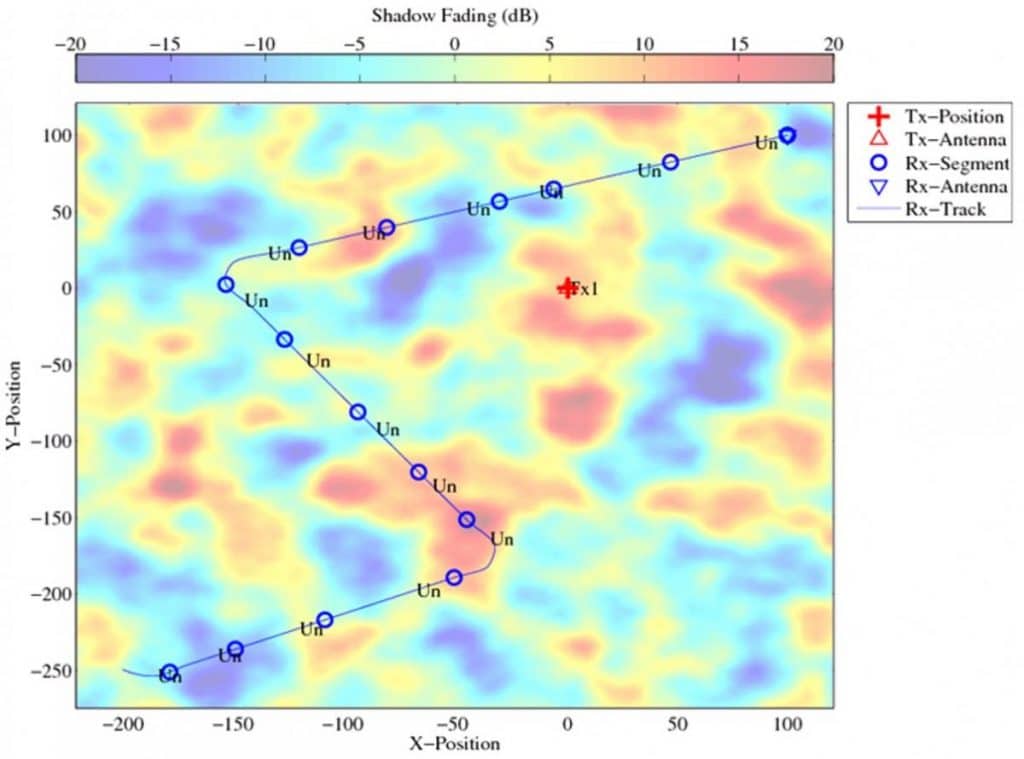

An indoor industrial radio environment is a multipath-rich, dynamically changing environment, and the propagation channel itself is unpredictable. For example, there is a robot or a fork lift moving in a production hall. Due to the mobility, reflections from the building structures and the machinery change constantly the radio channel properties. In the project, radio propagation in a steel factory and in assembly line halls was recorded and analyzed. As a result, the Fraunhofer QuaDRiGa radio channel model was enhanced to support dual-mobility in a multipath-rich industrial indoor environment. The extracted channel parameters can be also used in other geometric-stochastic channel models such as Keysight GCM to support simulation studies, both in the link and system levels.

What was most surprising in the measurement results?

Metallic walls and objects in the industrial halls create a rich scattering environment that provides surprisingly high signal levels even in situations where the direct line-of-sight (LOS) paths are blocked by obstacles. This enables designs of low power communication systems for locations where the direct path is obstructed.

What are the strengths of the wireless channel model you produced?

The strengths of the model are the extended modelling in 3D environment and simultaneous mobility of the transmitter and the receiver that are currently missing from the statistical models. The future trends of industrial processes are the virtual reality interface, flexibility of installations, and dynamic change of operational environment. Wireless control and communication enable all these.

What is the main take-away of your article?

The published results enable system designers to extend the radio propagation models into new communication scenarios and user cases in industrial environments.

How will your work continue in the same topic area?

We will dig further into 4G transition to 5G/6G relying on new millimeter wave (mmW) frequency bands. This is really intriguing as state-of-the-art propagation models are unable to simulate the radio propagation in industrial environment at these frequencies. It also calls for further research of the basic propagation mechanisms. The mmW communication devices need to be tested wirelessly utilizing Over the Air connectivity, because they simply do no longer have connectors for wired test setups.